How to enter a purity factor for a standard - Tip13

Article number: 50275

OBJECTIVE or GOAL

When we purchase an analytical standard, the supplier provides a certificate of analysis that includes the purity of the standard. We need to incorporate that purity factor into Empower so that our calibration curve reflects the purity.

ENVIRONMENT

- Empower

PROCEDURE

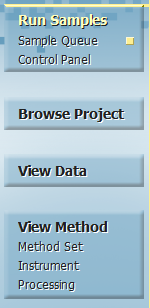

- Click Browse Project in the navigation bar when using the QuickStart interface.

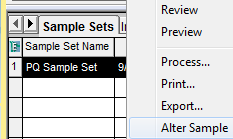

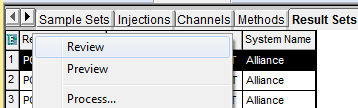

- Click the Sample Sets tab, right-click on a sample set, and select Alter Sample.

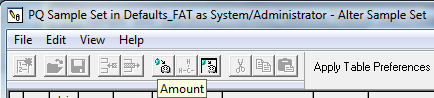

- Click the Amount tool.

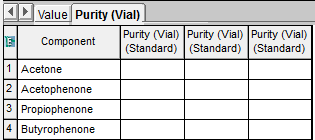

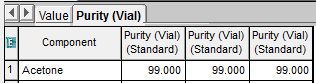

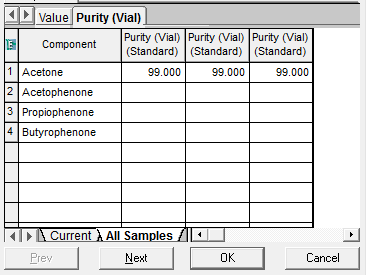

- Click the Purity (Vial) tab.

- Enter the Purity for the component or components. The allowable range is 0.001% to 150.000%.

- Click OK on the Component Editor.

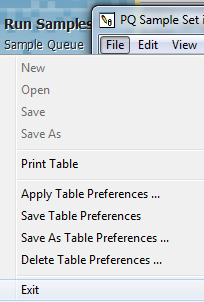

- Save all changes in Alter Sample and exit.

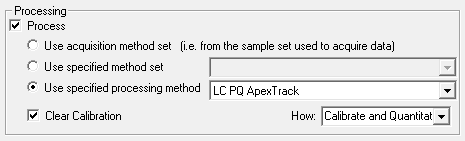

- Right-click on the Sample Set and select Process. Select the proper method set or processing method and click OK.

- Select the Result Sets tab, right-click on the new Result Set, and select Review.

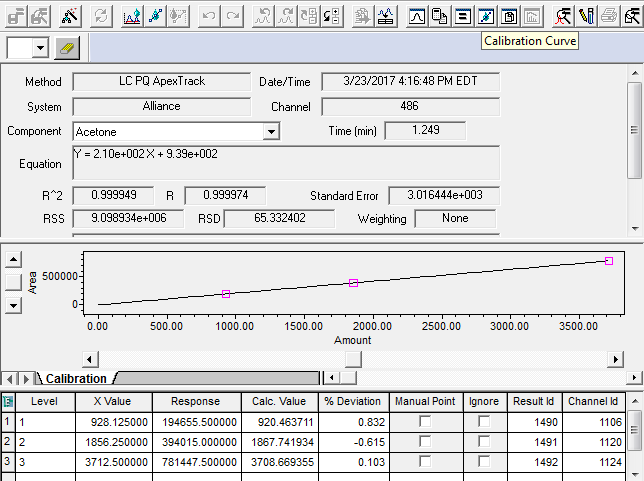

- Click in the tool bar and observe the X Value in the point table. In the case of acetone, the amount entered for standard 1 was 937.500. With the purity of 99.0 entered, the amount used for the calibration curve is 928.125.

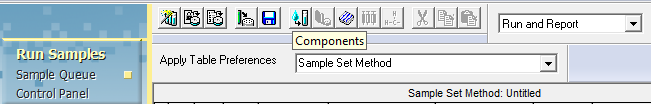

- You can enter the purity either after the run in Alter Sample or prior to data acquisition by clicking the Components tool while in the Run Samples area and then following steps 4 through 6 above.

ADDITIONAL INFORMATION

id50275, EMP2LIC, EMP2OPT, EMP2SW, EMP3GC, EMP3LIC, EMP3OPT, EMP3SW, EMPGC, EMPGPC, EMPLIC, EMPOWER2, EMPOWER3, EMPSW, SUP