Seal pack geometry fault on Alliance 2690/2695 Separations Module - WKB5360

Article number: 5360

SYMPTOMS

- Error: "Seal pack geometry fault (1 or 2)" occurs during Adjust Seals diagnostic.

ENVIRONMENT

- Alliance HPLC System

- 2695 Separations Module

- Applies to all versions of the Alliance injector assembly

- Performance Maintenance (PM)

CAUSE

During performance maintenance or installation of a new seal pack, the sensor position shifted out of range.

FIX or WORKAROUND

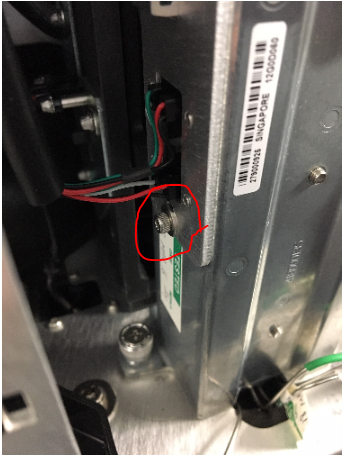

- Locate the screw on the injector assembly that holds in place the sensor plate. Loosen it with a T10 about 1-2 turns. Refer to the picture below.

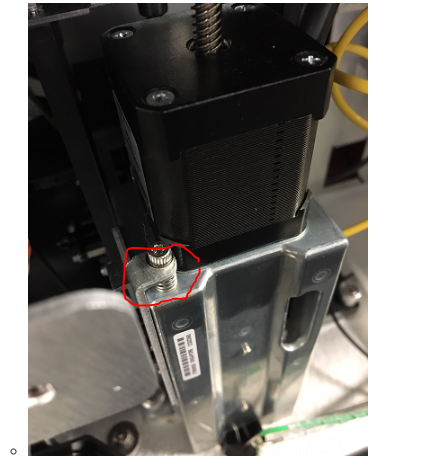

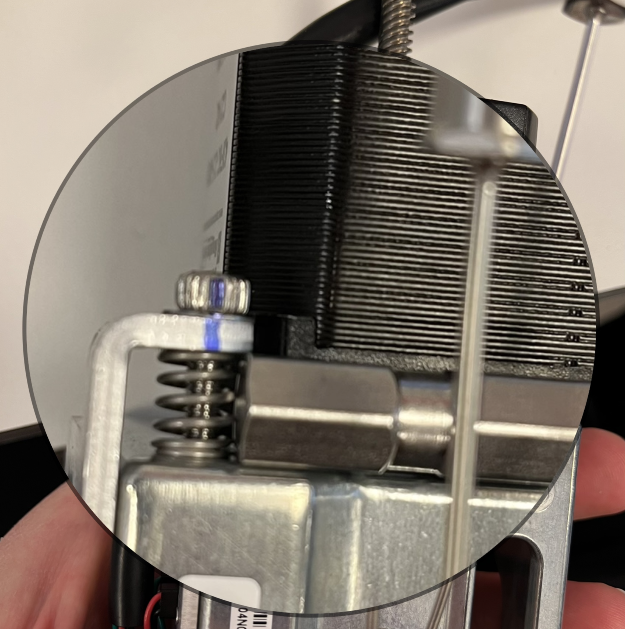

- Inspect the sensor plate adjustment screw as seen in the picture below. The screw has a spring on it.

- Start by zeroing the sensor gap (the gap between the top of the injector and the top of the spring) to the prescribed 5/16 inch. A 5/16-inch union or wrench can be used for measure. After that take the union away and tighten 1 turn.

- Run the adjust seals diagnostic

- If the adjust seals diagnostic passes, lock down the screw that holds the sensor plate in place.

- If the result of the diagnostic gives Error: "seal pack geometry fault (2)", move the sensor down.

- Turn the top sensor screw 1/2-turn at a time, clockwise, to bring the sensor down. Rerun the adjust seals diagnostic after each 1/2 until it passes.

- Once the adjust seals diagnostic passes, lock down the screw that holds the sensor plate in place.

- If the result of the diagnostic gives Error: "seal pack geometry fault (1)", move the sensor up.

- Turn the top sensor screw 1/2-turn at a time, counterclockwise, to bring the sensor up. Rerun the adjust seals diagnostic after each 1/2 until it passes.

- Once the adjust seals diagnostic passes, lock down the screw that holds the sensor plate in place.

ADDITIONAL INFORMATION

1/2-turn adjustment results in value changing by approximately 7 motor steps, though this value may change depending on the specific tolerances of the adjustment screw.

For additional information, refer to Article: What does "Error: Seal Pack Geometry Fault" mean on an Alliance?

If after zeroing the sensor gap and adjusting the sensor plate continues to give "seal pack geometry fault(1)" replacement of the injector assembly may be necessary.

Phase II injector assembly: 700002789

Performance plus injector assembly: 700011785

NB. If parts are replaced another article should be created or linked to.