H-Class FTN General Failure: Not ready to start run - WKB3295

SYMPTOMS

- H-Class FTN "General Failure: Not ready to start run" error occurs during injection sequence and the run fails to start.

- Occurs whether the gradient start time is programmed before or after injection.

- Occurs when the gradient start time is programmed by volume or time.

ENVIRONMENT

- ACQUITY H-Class Quaternary Solvent Manager (QSM)

- ACQUITY H-Class Sample Manger FTN (SM-FTN)

- DP2020 R1 installed

CAUSE

Defect SCR 29812 recognized as an "General Failure: Not ready to start run" error is observed when:

- Unique pre-injection large volumes

- Lower flow rates

- Changing solvent/pressure conditions occurring before injection

This error is amplified by the number of strokes necessary to deliver the requested volume within a minute of delay volume.

FIX or WORKAROUND

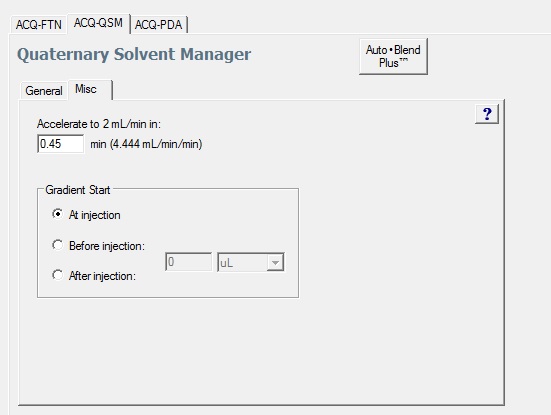

- Reduce the programmed gradient start by time or volume to less than one minute or comparable to one minute by volume.

- If error persists when programming by volume, convert that volume (ul) to time (min).

- If error persists when programming by time, convert that time (min) to volume (ul).

- It may be necessary to adjust the gradient start parameter in small time/volume increments that will operate the systems gradient start function without error.

ADDITIONAL INFORMATION

- Driver Pack 4 SR1 includes a partial fix to reduce the probability that this error will occur when timing the gradient start volumetrically.

- Reference article 8567, "How to program a gradient start when transferring a method to an ACQUITY System".

At the start of a run with delay time/volume the “Gradient Smart Start” / “Quantum Sync” feature causes the pump and autosampler to quickly negotiate their respective time to prepare for an injection based on the method conditions. While it’s usually the autosampler that’s slow and needs to get started before pump, the pump can become the slow module when we program the larger delay volumes (such as 145 to 200ul) at lower flow rates where the gradient is started even before the autosampler.

This timing is all calculated at the beginning of each injection run with the QSM timing based on the current conditions (flow rate, stroke length, compressibility, etc) and commits to initiating the injection based on an integer number of QSM stokes to achieve the programmed delay volume. All timing is committed and both the QSM and Autosampler work in parallel to try to meet up at the same point in time. The timing is such that the autosampler must be ready before the QSM and the calculations bias this such that the autosampler should be ready nominally about 5 seconds before the QSM reaches its calculated stroke to issue the inject start signal.

The autosampler MUST be ready to inject when the QSM sends this inject start signal o that calculated stroke boundary, or this error will be generated.

Small errors in the per stroke timing can be multiplied by larger programmed delay volumes which require in a larger number of pump strokes before the actual injection. This can create an issue with the calculation.

Please also note that the per stroke timing calculations are based on the current pump stroke timing and assume the solvent conditions will remain constant until the injection occurs. This assumption, however, may not be the case if the system is still re-equilibrating back to the exact initial gradient conditions in the system. If the pressure is still changing, even slightly, this will impact the per stoke timing. Again, any error in the calculated per cycle timing will be amplified by the number of strokes before the injection.

The autosampler must win this QSM vs. Injection race or you’ll see this error. The autosampler is just saying it was not yet ready.