Alliance compression check failure with 200-µL sample loop installed - WKB25932

Article number: 25932

SYMPTOMS

- Alliance fails compression test with 200-µL sample loop and 250-µL syringe

- Instrument passes all diagnostics using 100% methanol with 100-µL sample loop and 250-µL syringe

- Successfully adjusted seals, and measurements are within specified criteria or range

- High-pressure motor valves 1 and 2 pass leak test diagnostics

ENVIRONMENT

- Alliance HPLC System

- 2695 Separations Module

CAUSE

Compressible volume is increased when conducting the compression test with larger sample loops.

- The parameters for the compression test were much too tight at anything below 20-psi delta decay with the larger sample loop.

FIX or WORKAROUND

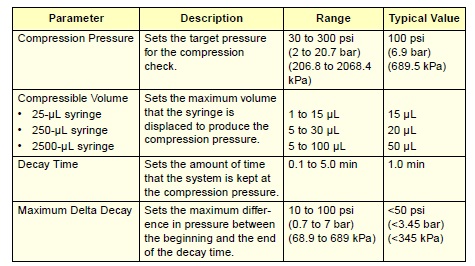

- Adjust the compression test parameters according to the default parameters recommended in the operators guide.

- Recommendation: use a max delta decay of 50 psi as the default.

- Change other parameters, such as the target compression pressure, only as necessary when working with larger sample loops and/or different solvent compressibility.

- Review the compression test guidelines outlined in the following operator's guides:

ADDITIONAL INFORMATION

Compression test passed with repeatable results with the 200-µL sample loop when delta decay was 50 psi and target compression pressure was 200 µL. This is within the acceptable range of parameters for characterizing the instrument using this diagnostic.