What is the service update for ACQUITY Sample Managers? - WKB229471

ENVIRONMENT

- H-Class PLUS SM-FTN PM Kit

- H-Class SM-FTN PM Kit

- ACQUITY SM PM Kit

- ACQUITY I-CLASS SM-FTN PM Kit

- I-Class PLUS SM-FTN PM Kit

- ACQUITY I-CLASS SM-FL PM Kit

- BIO FTN PM Kit

- H-Class PLUS Bio SM-FTN PM Kit

ANSWER

Due to unprecedented demand for our newest instruments, and while we bring further manufacturing capacity on stream, we are implementing an earlier than planned sustainability enhancement to our Performance Maintenance strategy for ACQUITY UPLC and H-Class Sample Managers.

For select service plan customers, using our insight into their applications and usage history, we are implementing a temporary review/inspect/replace action of the Valve POD by our service personnel for these systems.

In situations where our service teams determine that there is a low risk of failure within the next service contract period, the existing Valve POD will not be exchanged.

ADDITIONAL INFORMATION

What is the change?

-

PM kits with no injection valve pod have been created, which will be used for customers with the following criteria:

- "Full Support" service plan on the Sample Manager

- Injection Cycle Count of < 50,000 injections

- Customers usage/application uses non-complex sample matrices for their injections

- Service personnel need to conduct Inspection of the valve, review cycle count, and perform risk-based approach to replacement, given knowledge of cycle count and insight to customers usage and application as described above and understanding when the next PM visit will be scheduled.

- For clarity, Service Plan customers with complex sample matrices that have a historically reported impact on valve pod reliability or usage of more than 50,000 injections per year/service interval (i.e., if on two PM per year) should remain on the "full" Performance Maintenance Kits.

Why are we doing this?

- We understand that meeting the maintenance schedules for your instruments is important for your business success. Instead of delaying the PM for your entire system, because of a manufacturing constraint on one item, we are implementing a sustainability change ahead of schedule, that aims to reduce the risk to your business by completing the PM on the rest of your system on schedule.

Don't we recommend that the Valve POD is replaced annually?

- Yes, we continue to recommend that the POD is replaced on an annual basis to maintain uptime and that has not changed. However, in the situations described, the risk is understood to be very low (for this subset of customers) and by not implementing maintenance on time across the rest of the system, the risks to uptime and impact on system performance would be much higher than not replacing the Valve POD.

What if there are any issues with the Valve POD in the subsequent contract period?

- In the unlikely circumstances that an issue occurs, any issues subsequently encountered with the review/inspect/replace action of the Valve POD will receive priority response from our service teams and will be covered by the ‘full support’ service plan for your instrument.

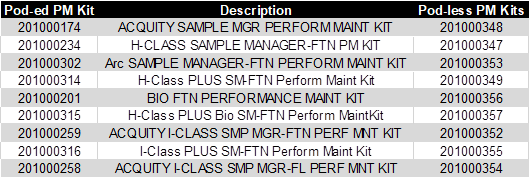

PNs for the PM kits with and without pod: