How is needle cleaned on ACQUITY UPLC Sample Manager using a strong wash solvent and a weak wash solvent? - WKB205077

ENVIRONMENT

- ACQUITY UPLC Sample Manager

ANSWER

Weak wash solvent: Mobile phase composition, initial composition recommended for gradient (salt not included)

Strong wash solvent: Solvent that is strong enough to dissolve the sample (salt not included). Example: 100% organic solvent

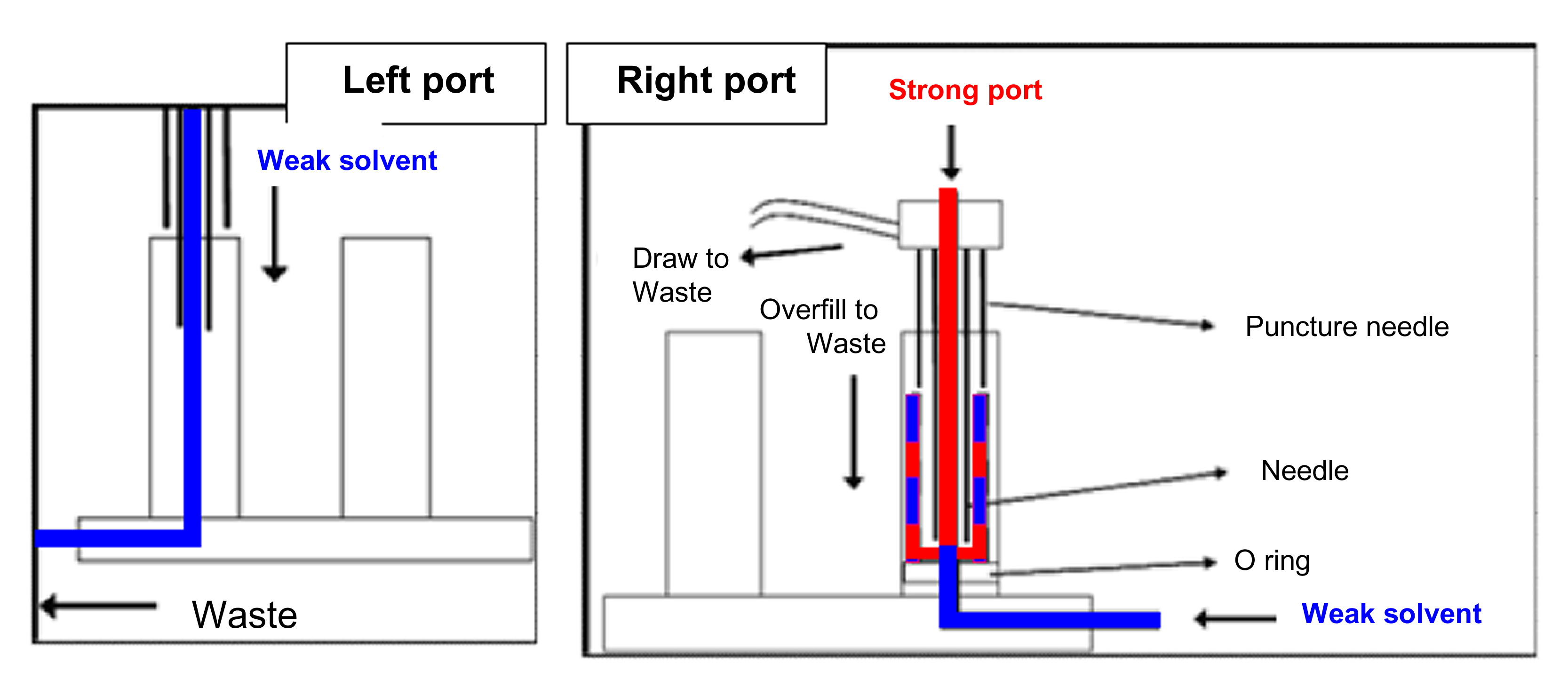

- Wash port

Left: Wash the inside of the needle with a weak solvent.

Right: Wash the inside/outside of the needle with a strong/weak solvent.

■ Left port

① Wash the inside of the needle with a weak solvent.

■ Right port

② Wash the inside of the needle with a strong solvent from top, while pushing up with a weak solvent from bottom at the same time.

* The outside of the needle (the gap between the drilling needle) is cleaned while the two solvents are mixed, and the liquids are drained to waste from top.

③ Wash the inside of the needle with a weak solvent.

④ Drain the liquid remaining in the wash port to waste.

* ① occurs before sample aspiration and ①-④ occur after injection.

ADDITIONAL INFORMATION

You can obtain a higher cleaning effect by increasing the volume of the strong/weak solvent.

The setting is made in "Instrument Method (Empower)". The ratio of weak wash solvent to strong wash solvent should be approximately 3:1.

id205077, eluent, UPBSMIVD, UPIBSMIVD, UPLCCHIVD, UPLCCOLHTR, UPNBINARY, UPSMIVD, UPSMPMGR, UPSMPMGR