Purity (Vial) vs Purity (Component) - Tip292

OBJECTIVE or GOAL

Understand the difference between Purity (Vial) and Purity (Component).

ENVIRONMENT

- Empower

- Empower Tip of the Week #292

PROCEDURE

STEP 1

To better understand what the different fields mean, let’s look at calibration and quantitation without use of these fields, starting with External Standard Calibration. When you calibrate, the value displayed in the Amount field is the same as what was specified in the Component Editor for the standards (Figure 1).

STEP 2

When you quantitate, you see the calculated Amount for the components in the sample (Figure 2).

STEP 3

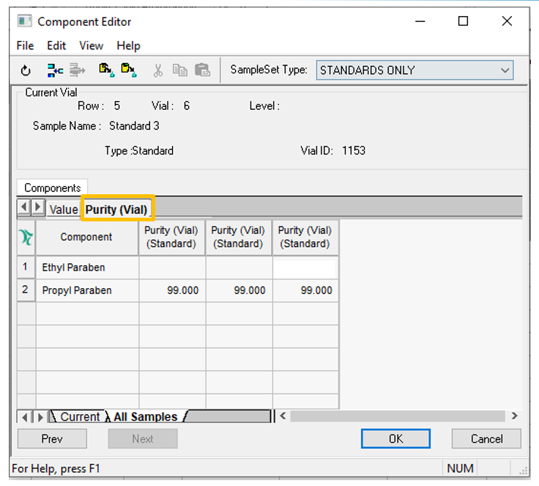

The Purity (Vial) field, found in the Component Editor, is where a purity value for the standard components can be specified. The allowable range is 0.001 – 150.000. In the example, a value of 99.000 was specified for Propyl Paraben (Figure 3).

STEP 4

When you calibrate, the amount for Propyl Paraben is adjusted from 0.02000 to 0.019800 based on the purity value of 99.000. The Purity (Component) field can be added to the Peaks table in Review to display the purity value specified in the Component Editor (Figure 4).

STEP 5

When you quantitate, you see the calculated amount for Propyl Paraben goes from 0.065514 (Step 2) to 0.064859. The Purity (Component) field displays 100 for the sample components, which essentially does nothing to the calculation (Figure 5).

STEP 6

With internal standard calibration and quantitation, you may want to specify a purity value for the internal standard that goes into all standards and samples. In this example, Propyl Paraben is the internal standard (Figure 6).

STEP 7

When you calibrate, the amount for the internal standard is adjusted based on the purity value specified in the Component Editor (Figure 7).

STEP 8

When you quantitate, the calculated amount for Ethyl Paraben is affected by the purity value for the internal standard (Figure 8).

ADDITIONAL INFORMATION

This can be done with either the Pro or QuickStart interface.