UPC2 system high-pressure shutdown when performing gradient with high % co-solvent - WKB15645

Article number: 15645

SYMPTOMS

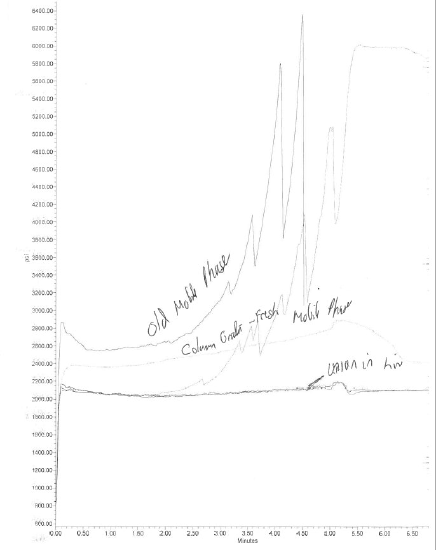

- High pressure and shutdown when using second 30cm Single Zone Column Manager (CM-30S)

- Initial conditions of gradient are stable at 95% CO2 (A) and 5% acetonitrile co-solvent (B)

- At injection, pressure increases as the gradient approaches 40%A and 60%B

- Overpressure occurs during runtime on the second injection

- All eight columns positions in the secondary CM-30S exhibit this overpressure and system shutdown

- Injections made across all columns in the primary CM-30S do not overpressure

- Isocratic method results in good performance across all seven column positions in the primary CM-30S

- Flushing the system overnight, high-pressure shutdowns during injections; re-traced flow paths and checked for blockages

- ABPR health check and diagnostic pass

- CM-30S inlet and outlet tubing new

- Inject, auxiliary, and column switching valve cartridges new

- 2998 flow cell new

- System with fresh solvents used for UPC2 startup testing using a union (no column) and methanol and CO2—pressure and system were fine

- System with the chemists solvent (ACN + 0.2% isopropylamine) and up to 65% co-solvent—the system went over pressure and shut down

- Major spikes observed toward the higher composition of co-solvent

ENVIRONMENT

- ACQUITY UPC2 system:

- ACQUITY UPC2 Binary Solvent Manager (ccBSM)

- ACQUITY UPC2 Sample Manager - Fixed Loop (SM-FL)

- ACQUITY UPC2 30cm Single Zone Column Manager (CM-30S)

- ACQUITY UPC2 Convergence Manager

- ACQUITY 2998 PDA

CAUSE

Co-solvent, mobile phase contamination from topping off solvents

- Co-solvent glass bottle dated November 2015

- Suspect water content in mobile phase contributed to high pressure; composition of co-solvent increased above 50%

FIX or WORKAROUND

Perform a 100% acetonitrile co-solvent flush through the entire UPC2 system:

- Connect each module one at a time in order to wash off any contamination or poor quality solvent from the system components

- Flush each module (approximately one hour) and monitor pressure because high pressure could still occur

ADDITIONAL INFORMATION

id15645, 2998, 2998B, 2998SFC, A-10PDA, eluent, UPC2BSM, UPC2CMA, UPC2CNVMGR, UPC2SMFL