How to prime the ACQUITY UPLC BSM solvent lines and seal wash - WKB288781

OBJECTIVE or GOAL

How to prime the ACQUITY UPLC BSM solvent lines and seal wash

ENVIRONMENT

- ACQUITY UPLC BSM

PROCEDURE

Priming is used to prepare a new system or binary solvent manager for use, change reservoirs or solvents, and run the system after it has been idle for more than 4 hours. During priming, the vent valve moves to Vent position to both ensure minimal backpressure and direct the flow to waste.

The flow rate during priming is 4 mL/min for each pump being primed.

Tip: If you are priming a dry binary solvent manager, using a syringe shortens the time required to complete priming.

Ensure the solvent reservoirs have enough solvent for adequate priming and the waste container has sufficient capacity for used solvent. The priming flow rate is 4 mL/min for each pump, or 8 mL/min total. For example, priming both solvents for 5 minutes requires approximately 20 mL of each solvent.

To prime a dry binary solvent manager

How to prime the ACQUITY UPLC BSM solvent lines

1. Open the instrument’s front door.

2. Locate the appropriate solvent vent line.

3. In the ACQUITY UPLC Console, select Binary Solvent Manager from the system tree.

4. In the binary solvent manager information window, click Control > Prime A/B Solvents.

5. In the Prime A/B Solvents dialog box, select solvent A and/or B.

6. In the Time box, specify the number of minutes from 0.1 through 60.0. Default: 1.0 minute

Recommendations: Prime the binary solvent manager until a steady flow exits the vent tube (typically 7 to 10 minutes).

7. Click Start. When solvent flows out of the vent line without bubbles, the path is primed.

8. Repeat step 3 through step 7 to prime the other solvents.

Requirement: There must be solvent in the A1, A2, B1, and B2 reservoirs for the degasser to function correctly.

To prime a dry binary solvent manager using a syringe

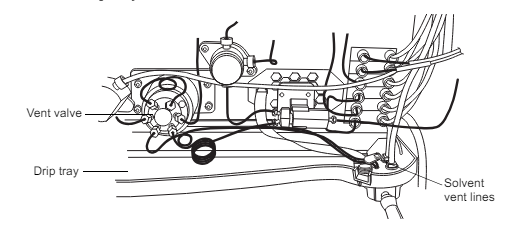

1. Open the instrument’s front door.

2. Locate the appropriate solvent vent line.

NOTE: If you are priming solvent A, follow the stainless steel vent line that is labeled “A-VENT” from port 4 on the vent valve, and lift it out of the drip tray.

If you are priming solvent B, follow the stainless steel vent line that is labeled “B-VENT” from port 1 on the vent valve, and lift it out of the drip tray.

3. Push the syringe plunger fully into the syringe barrel.

4. Connect the tubing adapter to the syringe.

5. Connect the syringe assembly to the short length of PharMed tubing, and then connect the short length of PharMed tubing to the solvent vent line you located in step 2.

6. In the ACQUITY UPLC Console, select Binary Solvent Manager from the system tree.

7. In the binary solvent manager information window, click Control > Prime A/B Solvents.

8. In the Prime A/B Solvents dialog box, select solvent A1.

9. In the Time box, specify the number of minutes from 0.1 through 60.0. Default: 1.0 minute Recommendation: Prime the binary solvent manager until a steady flow exits the vent tube (typically 3 minutes).

10. Click Start.

11. Slowly draw back on the syringe plunger to pull solvent through the solvent path. When solvent flows out of the vent line without bubbles, the path is primed.

12. Remove the syringe from the vent line, and reconnect the vent line to the drip tray.

13. Repeat step 2 through step 12 for solvent A2, B1, and B2.

Requirement: The reservoirs and solvent lines for solvents A1, A2, B1, and B2 must not be empty. Otherwise the degasser does not function correctly.

To perform a seal wash prime

How to prime the seal wash and pump in an ACQUITY UPLC BSM.

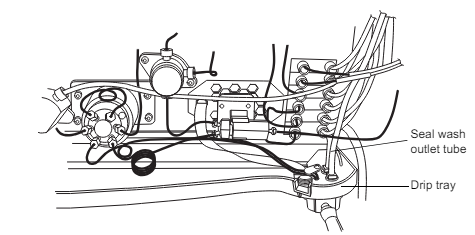

1. Ensure the seal wash inlet tube is in the solvent reservoir.

2. Remove the seal wash outlet tube from the right-hand side of the drip tray

3. Push the syringe plunger fully into the syringe barrel.

4. Connect the tubing adapter to the syringe and then connect the syringe assembly to the outlet tubing from the seal wash system.

5. In the ACQUITY UPLC Console, select Binary Solvent Manager from the system tree.

6. Click Control > Prime seal wash, and then click Yes to begin the seal wash priming process.

7. Slowly draw back on the syringe plunger to pull seal wash solvent through the system.

8. When the seal wash solution begins to flow into the syringe without major air bubbles, disconnect the tubing and reinstall it on the fitting on the drip tray.

9. Click Control > Prime seal wash, and then click Yes to stop the priming

Click here to review procedure in the UPLC ACQUITY operator Guide.

ADDITIONAL INFORMATION

VIDEOS on Waters.com

How to prime the ACQUITY UPLC BSM solvent lines

How to prime the seal wash and pump in an ACQUITY UPLC BSM.

id288781, UPBINARY, UPBSM+, UPIBSM, UPIBSM+, UPPBSM