What does "textured needle" mean? - WKB207757

ENVIRONMENT

- ACQUITY UPLC H-Class PLUS

- ACQUITY UPLC H-Class Bio PLUS

- ACQUITY UPLC I-Class PLUS

ANSWER

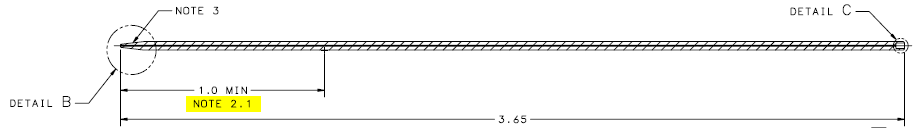

The non-textured (old-style) needle is electropolished with a Rα value less than or equal to 16 µIN (max). (Length of needle electropolished to this Rα value is indicated with Note 2.1 in the picture below.)

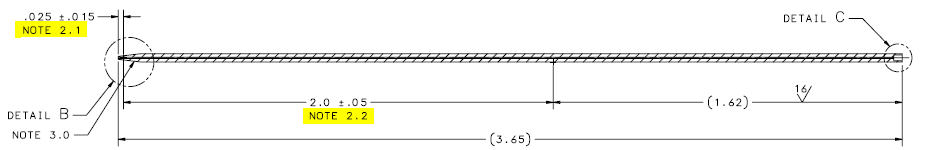

The textured (new-style) needle has two electropolishing steps:

- The tip of the needle (indicated Note 2.1) is electropolished with a Rα value less than or equal to 16 µIN (max).

- The rest of the needle (indicated Note 2.2) is electropolished with a Rα value of 15–30 µIN.

Non-textured needle:

Textured needle:

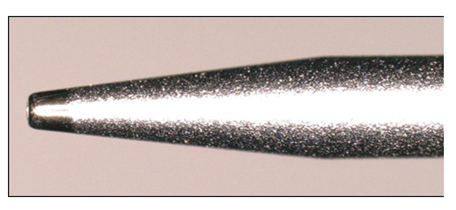

The following image shows a textured needle. The tip remains smooth, while the rest of the needle has a textured surface. The non-textured needle would be smooth along the entire length of the needle.

ADDITIONAL INFORMATION

Rα value is calculated as the Roughness Average of surface measured microscopic peaks and valleys.

Refer to external sites to learn more about Rα value: Calculating surface roughness

There is no requirement to electropolish the inside of the needle, so it is not done.

The textured needle is designed to give better piercing performance with clear polyester heat seal and adhesive seal well plate covers.