Condensed water observed in the sample compartment of ACQUITY Sample Manager - FTN - WKB190871

SYMPTOMS

- Condensed water observed in the sample compartment of ACQUITY Sample Manager - FTN

ENVIRONMENT

- ACQUITY APC Sample Manager - FTN

- ACQUITY Arc Sample Manager FTN-R

- ACQUITY UPLC Sample Manager - Flow Through Needle (SM-FTN)

- ACQUITY UPLC Sample Manager - Flow Through Needle PLUS (SM-FTN PLUS)

CAUSE

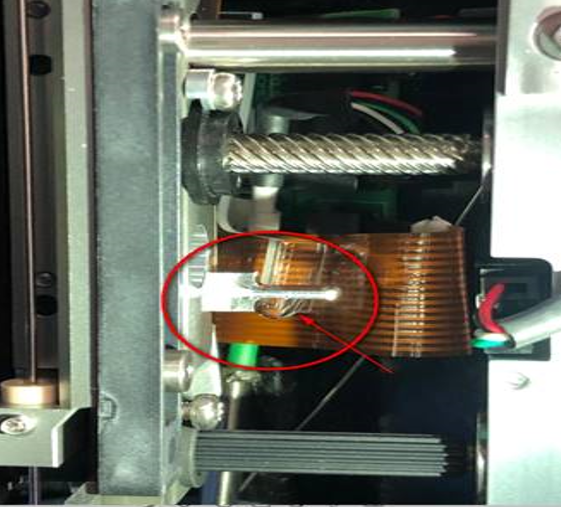

The cooling function of the FTN sample manager was on, making the temperature dropped to the dew point (while the humidity in the sample compartment was high enough to saturate the water vapor on the surface of the components), and the water vapor condensed to droplets.

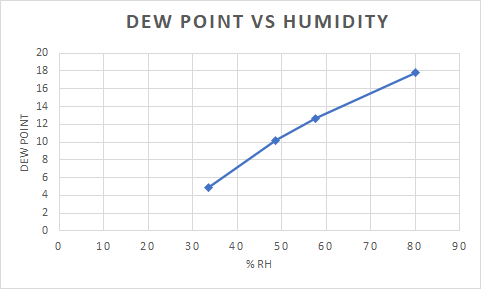

According to the installation guide, the "overall environment" required to install and use the instrument in the laboratory should be: "Ensure that the relative humidity in the laboratory is below (<) 80%, noncondensing." But as shown in the figure below, for the "local environment" in the sample compartment, with the temperature decreases, the humidity required for condensation to occur also decreases. For example, when the temperature in the sample compartment drops to 10 ℃, the humidity required for condensation to occur will be only about 48%; when the temperature drops to 4 ℃, a humidity of only 33% may cause condensation.

FIX or WORKAROUND

Try to reduce the humidity in the laboratory. If this fails to solve the condensation issue, it is recommended to adopt the following measures:

Perform the following procedure after using the sample compartment to maintain a low temperature (4-8 ℃) for a relatively long period (2-3 days), or after each time you use the sample compartment to maintain a low temperature.

-

Take the sample tray out of the sample compartment.

-

Set the sample compartment temperature to 30 ℃. (It takes about 50 minutes for the sample compartment temperature to rise from 4 ℃ to 30 ℃.)

-

When the temperature reaches 30 ℃, open the sample compartment door to ventilate and reduce the humidity in the sample compartment.

- Normal use can be restored after 30-60 minutes.

In addition, if applicable, you can also use dry nitrogen (≤ 20psi) to blow the sample compartment for 10-20 minutes to remove moisture.

Perform the procedure described above helps to avoid failure of the sensor, circuit board, or other components due to sample compartment constantly left in an environment with high humidity.

ADDITIONAL INFORMATION

The Defrost function of the sample compartment is to prevent frosting on the chiller, which has no help to reduce the humidity in the sample compartment and solve the condensation issue.

id190871, UPARBSMFTN, UPARHSMFTN, UPARPFTN, UPARSMFTN